Introduction: Radiation Cross-Linking

Within the realm of cutting-edge wire insulation technologies, the exceptional properties of XLETFE (Cross-Linked, Modified Ethylene Tetrafluoroethylene) insulated wire are intricately tied to the meticulous process of radiation cross-linking. Unveiling the intricate steps and mechanisms of the radiation cross-linking process, we delve into the scientific marvel that propels XLETFE to the forefront of advanced wire insulation materials.

Foundation: Ethylene and Tetrafluoroethylene

Chemical Building Blocks: XLETFE begins with a foundation of ethylene and tetrafluoroethylene, two key chemical constituents that form the basis of a polymer matrix essential for high-performance wire insulation.

Initiating Cross-Linking

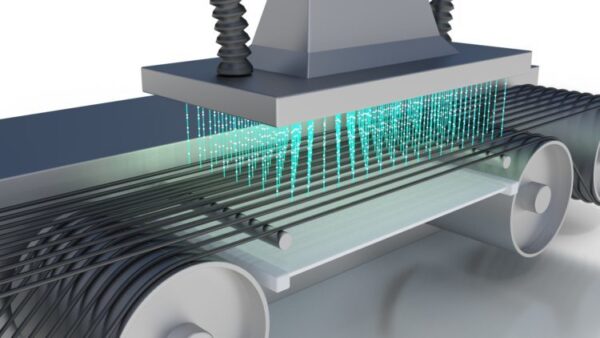

Ionizing Radiation as Catalyst: In radiation cross-linking, ionizing radiation serves as the catalyst to initiate the process. Typically, high-energy electrons act as the ionizing radiation, providing the necessary energy to induce cross-linking reactions within the polymer matrix.

Polymer Chain Reaction

Formation of Free Radicals: Ionizing radiation interacts with the polymer chains, causing molecular disruption and the formation of free radicals. These free radicals initiate a chain reaction by seeking stable molecular structures, leading to the creation of covalent cross-links between adjacent polymer chains.

Creation of Covalent Cross-Links

Strengthening Molecular Structure: The heart of the radiation cross-linking process lies in the creation of covalent bonds between polymer chains. These covalent bonds form a three-dimensional network, strengthening the molecular structure of XLETFE and enhancing its overall durability.

Enhanced Thermal Stability

Structural Modification: The introduction of cross-links brings about a structural modification in XLETFE, imparting enhanced thermal stability to the material. This structural resilience enables XLETFE to withstand elevated temperatures without compromising its integrity.

Mechanical Strength Augmentation

Fortifying the Material: The three-dimensional network of covalent bonds significantly augments the mechanical strength of XLETFE. This fortification ensures that the material remains resistant to mechanical wear, abrasion, and physical stresses encountered in challenging applications.

Controlled Process Parameters

Precision in Cross-Linking: Success in the radiation cross-linking process lies in the precise control of parameters such as radiation dose, exposure time, and other relevant factors. Engineers meticulously tailor these parameters to achieve the desired balance between enhanced properties and material flexibility.

Quality Assurance

Rigorous Testing Protocols: The final XLETFE insulated wire undergoes rigorous quality assurance testing to ensure the success of the radiation cross-linking process. Evaluations encompass thermal stability, mechanical strength, electrical performance, and resistance to environmental factors.

In Summary

The radiation cross-linking process stands as a pinnacle in the synthesis of XLETFE insulated wire, showcasing the precision and finesse achievable through advanced materials science. The interplay of ethylene and tetrafluoroethylene, combined with the meticulous application of ionizing radiation, results in a material that transcends conventional wire insulation capabilities. XLETFE, with its enhanced thermal stability and mechanical strength, exemplifies the forefront of scientific ingenuity and engineering excellence in the domain of high-performance wire insulation.